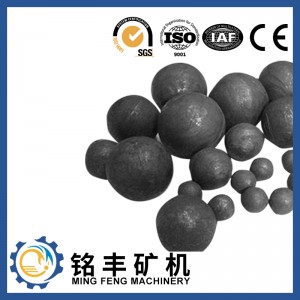

40 60 80 100 120 luhur / sedeng / low chrome ball mill liners

Nelepon kami pikeun inpormasi:Telepon: +86-18973821771

Ihtisar:

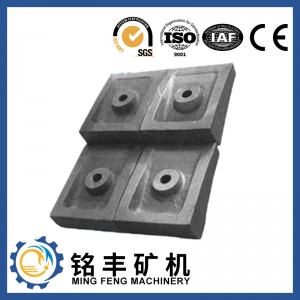

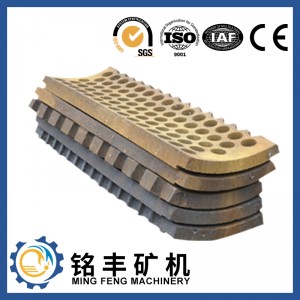

| Tipe | papan liner Crusher, plat pinding | ||

| Asalna | Cina | Kode HS | 84749000 |

| Kaayaan | Anyar | Ngagiling bijih | Kuarsa, bijih emas, klinker semén, jsb. |

| Tipe Mesin | Ball Mill Liner | Sertifikasi | ISO 9001:2008 |

| Bahan Utama | Mn13Cr2 , Mn18Cr2, Mn22Cr2, Cr22, Cr26 | ||

| Jenis Processing | Casting | Perlakuan permukaan | Polishing / Semprot-Cét |

| Casting Inspection | Alat Spéktrum bacaan langsung, Analisis Metallographic, Inspeksi Ultrasonik, Inspeksi Partikel Magnét, Inspeksi Sipat Mékanis | ||

| Paket Angkutan | Dipak dina Usuk / Kasus | ngajamin | Sarua jeung Asli |

| Kualitas | Tingkat Luhur | Pangalaman | Leuwih 30 Taun |

Parameter Téknis

| Komponén Kimia | ||||||||

| Tipe

| Komponén kimiawi | |||||||

| C | Si | Mn | Cr | Mo | Cu | P | S | |

| Low-Cr | 1.8-3.3 | ≤1.5 | 0.3-1.5 | 1-3 | ≤1.0 | ≤0.8 | ≤0.10 | ≤0.10 |

| Sedeng-Cr | 1.8-3.3 | ≤1.2 | 0.3-1.5 | 4-9 | ≤1.5 | ≤0.8 | ≤0.10 | ≤0.10 |

| Luhur-Cr | 1.8-3.3 | ≤1.2 | 0.3-1.5 | 10-18 | ≤1.0 | ≤1.2 | ≤0.10 | ≤0.06 |

| Superhigh-Cr | 1.8-3.3 | ≤1.2 | 0.3-1.5 | 19-35 | ≤2.0 | ≤1.2 | ≤0.10 | ≤0.06 |

| Diaméterna nominal | Toleransi diaméterna | Beurat Bola Tunggal Dina Rata-rata | |

| (mm) | (Inci) | (mm) | (g) |

| 20 | 0,75" | +2 -1 | 32 |

| 25 | 1” | 64 | |

| 30 | 1.25" | 110 | |

| 40 | 1,5" | 263 | |

| 50 | 2” | 513 | |

| 60 | 2,5" | +3 -2 | 888 |

| 70 | 2.75 | 1410 | |

| 80 | 3.25" | 2104 | |

| 90 | 3,5" | 2996 | |

| 100 | 4” | 4110 | |

| 110 | 4,5" | +4 -2 | 5457 |

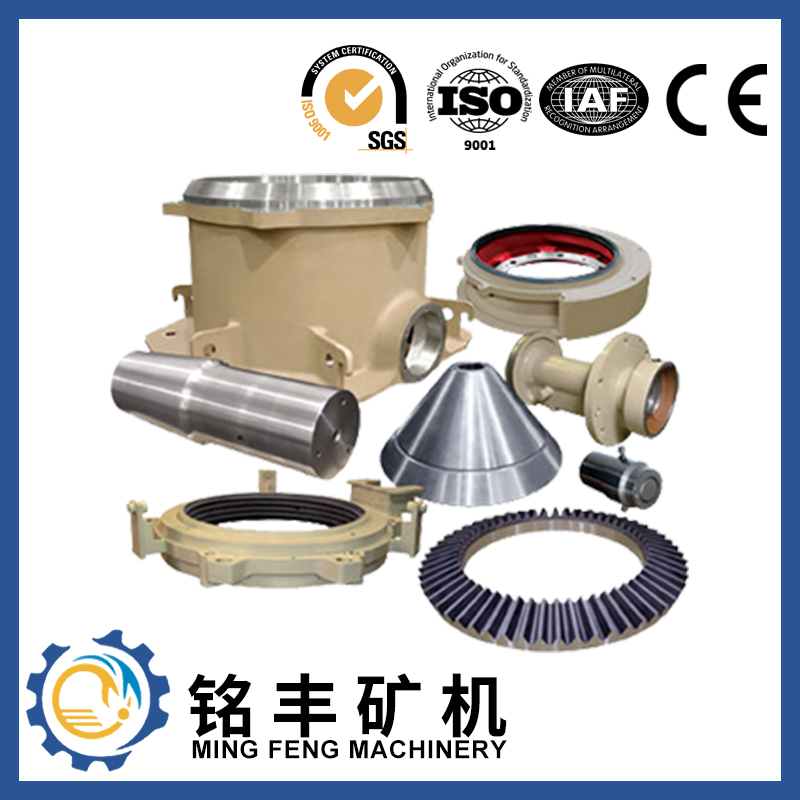

Bagian Crusher:

Kami gaduh suku cadang crusher ngagantian mesin precision kalebet sirah, mangkok, aci utama, liner stop kontak, stop kontak, bushing saendeng, bushings sirah, gear, countershaft, countershaft bushing, perumahan countershaft, liner korsi mainframe sareng seueur deui, urang tiasa ngadukung sadayana mesin anjeun pikeun suku cadang mékanis.

Naha milih urang?

1,30 taun pangalaman manufaktur, 6 taun pangalaman dagang asing

kontrol kualitas 2.Strict, laboratorium sorangan

3.ISO9001:2008, BIRO VERITAS

Tulis pesen anjeun di dieu sareng kirimkeun ka kami

HOT-SALE PRODUK

Kualitas Kahiji, Kasalametan Dijamin